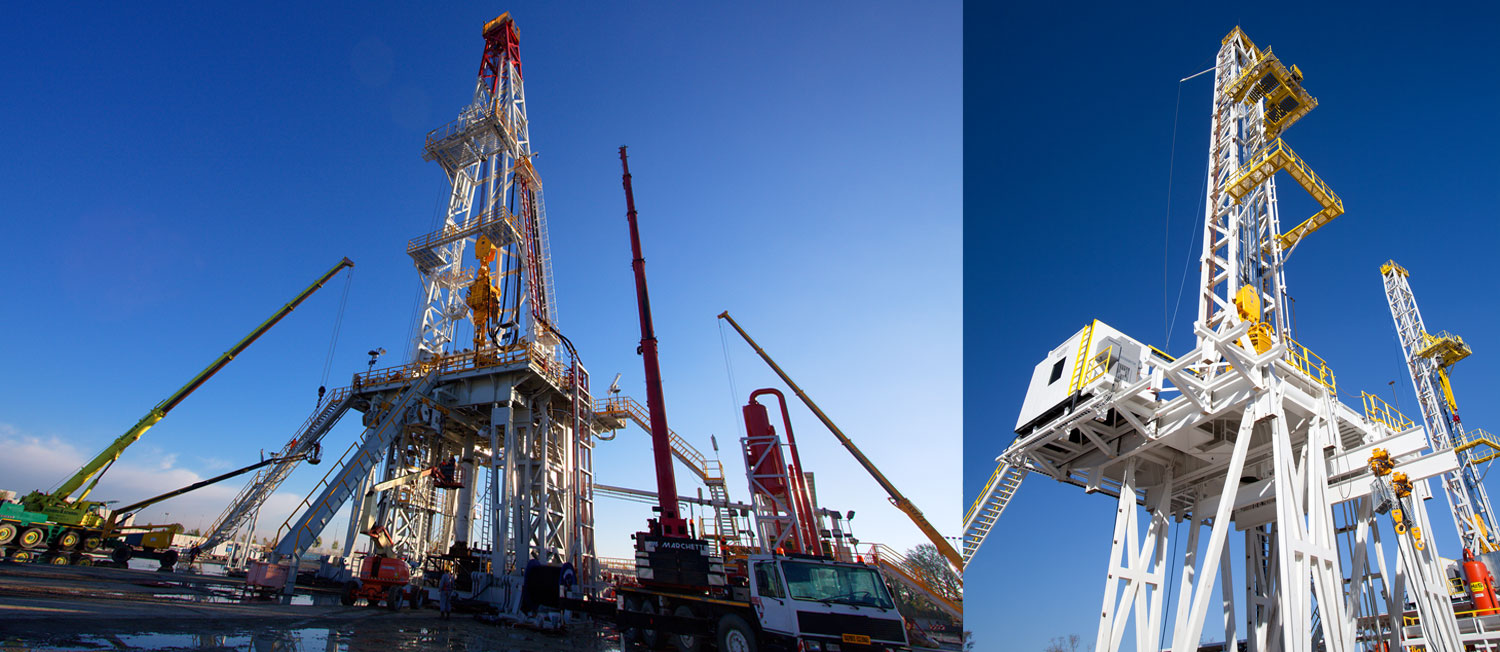

Drillmec’s deep roots in the manufacturing of drilling rigs begin around 1929 and since then the rig designs have been continuously improved by raising the pull-up capacity, enhancing safety, optimizing performance and minimizing environmental impact.

Enquiry about Land Rigs

Enter the security code shown above

Drillmec has a long history of over 100 years of manufacturing onshore drilling rigs. Over the years, several design improvements that enhanced safety, increased pull capacity, improved performance and reduced environmental impact have followed on. Drillmec started first with the introduction of conventional land rigs that inculcated Massarenti & Branham-design. Today they are full range land rig packages with varied capacity and specifications to handle all land drilling operations in different parts of the world. At Drillmec, we put our customer’s objectives and specifications into consideration in rig design and manufacturing to ensure it meets all the demands.

At Drillmec, we offer all our conventional land rigs with a full package that consists of top drives, drawworks, pipe handling systems, iron roughnecks, drilling control systems, rotary tables, power control units, low-pressure mud systems, catwalks and skidding systems. All these drilling equipment and systems are integrated into our customizable proprietary software DEEP (Drillmec’s Embedded Efficiency Platform). With DEEP you enjoy fully automated rig operations with easy controls of rig equipment thus increasing efficiency and performance.

We design out rigs to withstand harsh environmental conditions of different oil and gas fields. Our conventional land rigs can withstand varying extreme temperature conditions such as freezing -45°C and scorching at 55°C while offering safety and comfort to the personnel. In addition, our rigs are designed to reduce trailers with a compact system of special power trailers.

Our land drilling rigs feature a wide work area despite the compact design which provides more space that keeps the drilling crew safe. The advanced automation systems on our rigs remove manual thus making the operations safer.

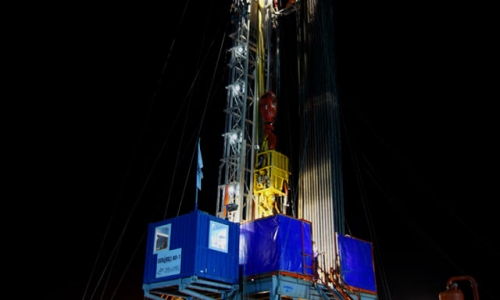

The integration of DEEP brings high performance as a result of numerous automated processes which saves time and resources. Many of the rig operations like tripping in and out can be done with minimal manpower because of automation.

Our onshore rigs are designed to support cluster/pad drilling with the dollies, skidding system, and walking system.

參數

Metric

| SWING LIFT | Hook Load | Lines | Setback Capacity | Mast Height | Mast Base | Substructure Height | |

|---|---|---|---|---|---|---|---|

| mt | mt | m | m | m | |||

| ELECTRIC TOP DRIVE ETD SERIES | lbs | lbs ft | lbs ft | lbs ft | psi | rpm | in |

| DM 750 | 340 | 12 | 181 | 43 | 8 | 9 | |

| DM 1000 | 454 | 12 | 272 | 46 | 9 | 11 | |

| DM 1300 | 590 | 14 | 362 | 48 | 11 | 11 | |

| DM 1500 | 680 | 14 | 362 | 46 | 9 | 11 | |

| DM 2000 | 907 | 16 | 454 | 49 | 12 | 14 | |

| HSL 750 | 340 | 12 | 181 | 43 | 8 | 9 | |

| HSL 1000 | 454 | 12 | 272 | 46 | 9 | 9 | |

| HSL 1300 | 590 | 14 | 362 | 47.8 | 11 | 11 | |

| 1000 SS | 454 | 12 | 272 | 46 | 9 | 9 | |

| 1300 SS | 590 | 14 | 362 | 46 | 11 | 12 | |

| 1500 SS | 748 | 14 | 500 | 46 | 11 | 12 | |

| 750 HSS | 340 | 12 | 181 | 43 | 8 | 9 |

USA

| SWING LIFT | Hook Load | Lines | Setback Capacity | Mast Height | Mast Base | Substructure Height | |

|---|---|---|---|---|---|---|---|

| lbs | lbs | ft | ft | ft | |||

| ELECTRIC TOP DRIVE ETD SERIES | lbs | lbs ft | lbs ft | lbs ft | psi | rpm | in |

| DM 750 | 750,000 | 12 | 400,000 | 142 | 25 | 30 | |

| DM 1000 | 1,000,000 | 12 | 600,000 | 152 | 30 | 35 | |

| DM 1300 | 1,300,000 | 14 | 800,000 | 156 | 35 | 35 | |

| DM 1500 | 1,500,000 | 14 | 800,000 | 152 | 30 | 35 | |

| DM 2000 | 2,000,000 | 16 | 1,000,000 | 160 | 40 | 45 | |

| HSL 750 | 750,000 | 12 | 400,000 | 142 | 25 | 30 | |

| HSL 1000 | 1,000,000 | 12 | 600,000 | 152 | 30 | 30 | |

| HSL 1300 | 1,300,000 | 14 | 800,000 | 157 | 35 | 35 | |

| 1000 SS | 1,000,000 | 12 | 600,000 | 152 | 30 | 30 | |

| 1300 SS | 1,300,000 | 14 | 800,000 | 152 | 35 | 39 | |

| 1500 SS | 1,650,000 | 14 | 1,100,000 | 152 | 35 | 39 | |

| 750 HSS | 750,000 | 12 | 400,000 | 142 | 25 | 30 |